The principle distinction between an induction seal and a warmth seal is the best way during which the seal is created. Induction sealing makes use of electromagnetic induction to generate warmth and create a tamper-evident seal, whilst warmth sealing makes use of warmth to bond two fabrics in combination.

Contents

- 1 Induction Seal vs Warmth Seal: What is the distinction?

- 2 Induction Seals

- 3 Advantages of The usage of an Induction Seal System

- 4

- 5 Demanding situations in Induction Seals

- 6 Warmth Seals

- 7 Advantages of The usage of a Warmth Seal System

- 8

- 9 Demanding situations in Warmth Seals

- 10 Upload High quality Assurance to Your Sealing Manner

- 11 The content material & evaluations on this article are the creator’s and don’t essentially constitute the perspectives of ManufacturingTomorrow

- 12 Feedback (0)

- 13 Publish A Remark

- 14 Featured Product

- 15 Cutting edge SWIR digicam for UAV primarily based spectral faraway sensing

Induction Seal vs Warmth Seal: What is the distinction?

Induction Seal vs Warmth Seal: What is the distinction?

Article from | MoviTHERM

The principle distinction between an induction seal and a warmth seal is the best way during which the seal is created. Induction sealing makes use of electromagnetic induction to generate warmth and create a tamper-evident seal, whilst warmth sealing makes use of warmth to bond two fabrics in combination. On this article, we damage issues down to check the advantages and demanding situations of an induction seal vs a warmth seal.

Induction Seals

An induction seal is one of those closure this is implemented to the highest of a container. It’s fabricated from a layer of subject material this is bonded to the highest of the container and creates a tamper-evident seal when it’s heated via induction.

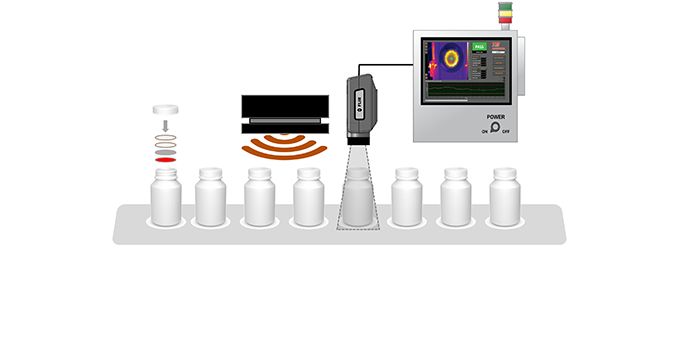

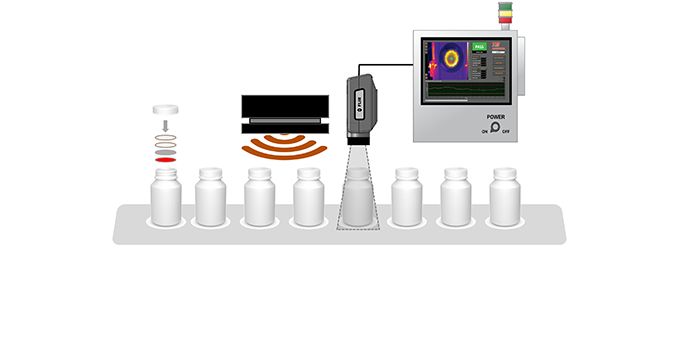

Induction sealing is a non-contact sealing procedure that makes use of electromagnetic induction to generate warmth in a conductive subject material. This warmth is used to seal the highest of a container, corresponding to a bottle or jar, with a view to keep the freshness and high quality of the product within.

Advantages of The usage of an Induction Seal System

There are a number of advantages to the usage of an induction seal system:

- Tamper-evident: Induction sealing creates a tamper-evident seal this is tricky to take away or damage with out leaving proof of tampering. This is helping to verify the integrity of the product within the container and may give peace of thoughts for customers.

- Preservation: Induction sealing is helping to keep the freshness and high quality of the product within the container. The seal is helping to stop contamination and will prolong the shelf lifetime of the product.

- Customization: Induction sealing apparatus may also be custom designed to paintings with a variety of container configurations and dimensions, making it appropriate for quite a lot of packages.

- Potency: Induction sealing is a quick and environment friendly sealing procedure that may be simply built-in right into a manufacturing line. It could possibly seal packing containers at a top velocity, which is able to lend a hand to extend productiveness.

- Versatility: Induction sealing can be utilized with quite a lot of container fabrics, together with plastic, glass, and steel. It may also be used with a variety of merchandise, together with meals, drinks, prescribed drugs, and private care merchandise.

Demanding situations in Induction Seals

There are a couple of demanding situations that may get up when the usage of induction sealing:

- Conductive subject material: Induction sealing calls for the usage of a conductive subject material, corresponding to aluminum foil, with a view to create the seal. If the fabric isn’t correctly implemented or isn’t of enough high quality, it won’t create a right kind seal.

- Container measurement and form: Induction sealing apparatus is in most cases designed to paintings with a particular vary of container configurations and dimensions. If the container is out of doors of this vary, it is probably not appropriate with the sealing apparatus.

- Container subject material: The fabric of the container too can impact the effectiveness of the induction seal. Some fabrics, corresponding to glass or positive kinds of plastic, is probably not appropriate for induction sealing.

Warmth Seals

A warmth seal, then again, is one of those sealing procedure that makes use of warmth to bond two fabrics in combination. Warmth sealing is ceaselessly utilized in packaging to seal luggage or pouches, or to seal the perimeters of plastic sheets or motion pictures. This sort of sealing procedure may also be carried out the usage of quite a lot of strategies, together with scorching bar sealing, impulse sealing, and steady sealing.

Advantages of The usage of a Warmth Seal System

There are a number of advantages to the usage of a warmth seal system:

- Velocity: Warmth sealing is a quick and environment friendly sealing procedure that may be simply built-in right into a manufacturing line. It could possibly seal luggage or pouches at a top velocity, which is able to lend a hand to extend productiveness.

- Customization: Warmth sealing apparatus may also be custom designed to paintings with a variety of fabrics and seal configurations, making it appropriate for quite a lot of packages.

- Versatility: Warmth sealing can be utilized with quite a lot of fabrics, together with plastic motion pictures and luggage, paper merchandise, and foil-lined fabrics. It may also be used to seal a variety of merchandise, together with meals, drinks, prescribed drugs, and private care merchandise.

- Reliability: Warmth sealing is in most cases thought to be a competent sealing approach that may create sturdy, constant seals which are proof against tampering and will face up to publicity to quite a lot of environmental prerequisites.

- Ease of use: Warmth sealing apparatus is in most cases simple to perform and care for, making it appropriate for companies of all sizes. General, some great benefits of the usage of a warmth seal system rely at the particular software and the fabrics being sealed.

Demanding situations in Warmth Seals

There are a couple of demanding situations that may get up when the usage of warmth sealing:

- Subject material compatibility: Warmth sealing calls for the usage of fabrics which are appropriate with the sealing procedure. If the fabrics being sealed don’t seem to be appropriate, the seal is also susceptible or won’t cling up over the years.

- Temperature: Warmth sealing calls for a particular temperature with a view to create a robust, dependable seal. If the temperature is just too low, the seal is probably not sturdy sufficient. If the temperature is just too top, the fabrics being sealed is also broken or would possibly turn into too susceptible to carry up over the years.

- Velocity: Some warmth sealing processes, corresponding to steady sealing, require a top stage of velocity and precision with a view to be fine. If the sealing procedure isn’t speedy sufficient, it will lead to susceptible or inconsistent seals.

- Force: Warmth sealing ceaselessly calls for the applying of drive with a view to create a robust seal. If the drive isn’t enough, the seal is also susceptible or would possibly fail.

Upload High quality Assurance to Your Sealing Manner

Thermal seal inspection can be utilized for high quality assurance in warmth seals and induction seals via figuring out any defects or inconsistencies within the sealing procedure. This may lend a hand to make sure that the seals are sturdy, constant, and dependable, which is essential for protecting the standard and integrity of the product within the container.

In relation to warmth seals, thermal seal inspection can be utilized to spot any defects or inconsistencies within the sealing procedure that can lead to susceptible or damaged seals. This may also be specifically essential for merchandise which are delicate to contamination or require an extended shelf lifestyles.

In relation to induction seals, thermal seal inspection can be utilized to make sure that the seals are correctly implemented and are of enough high quality to keep the product within the container. This may lend a hand to make sure that the product stays contemporary and of prime quality till it’s opened via the patron.

General, thermal seal inspection is the most important high quality assurance instrument for each warmth seals and induction seals, because it is helping to make sure that the seals are sturdy and dependable, and that the product within the container is safe from contamination and different environmental elements.

The content material & evaluations on this article are the creator’s and don’t essentially constitute the perspectives of ManufacturingTomorrow

Feedback (0)

This submit does no longer have any feedback. Be the primary to depart a remark under.

Featured Product

Cutting edge SWIR digicam for UAV primarily based spectral faraway sensing

Allied Imaginative and prescient’s compact and light-weight weight Alvium SWIR (quick wave infrared) cameras are the best option to construct cost-effective OEM programs utilized in embedded and system imaginative and prescient packages. The cameras fortify a spectral vary from 400 nm to 1700 nm at top quantum efficiencies. This permits to seize pictures in each the visual and SWIR spectra with a unmarried digicam and permits customers to cut back general device prices! Provided with Sony’s IMX990 and IMX991 SenSWIR InGaAs sensors, Alvium SWIR cameras ship top symbol high quality and body charges. This makes them smartly suited to drones or hand-held gadgets utilized in more than a few industries corresponding to, agriculture, mining, sun mobile inspection or clinical.

Supply By way of https://www.manufacturingtomorrow.com/article/2023/03/induction-seal-vs-heat-seal-whats-the-difference/20225